In the dynamic realm of engineering, the Simcenter portfolio from Siemens stands out as a pivotal toolset that addresses modern engineering challenges. This integrated suite of software solutions is designed to empower engineers to navigate the complexities of product development through simulation, testing, and data management. Below, we’ll explore the key elements of the Simcenter portfolio, drawing insights from both the presentation and the accompanying information.

Understanding the Simcenter Portfolio

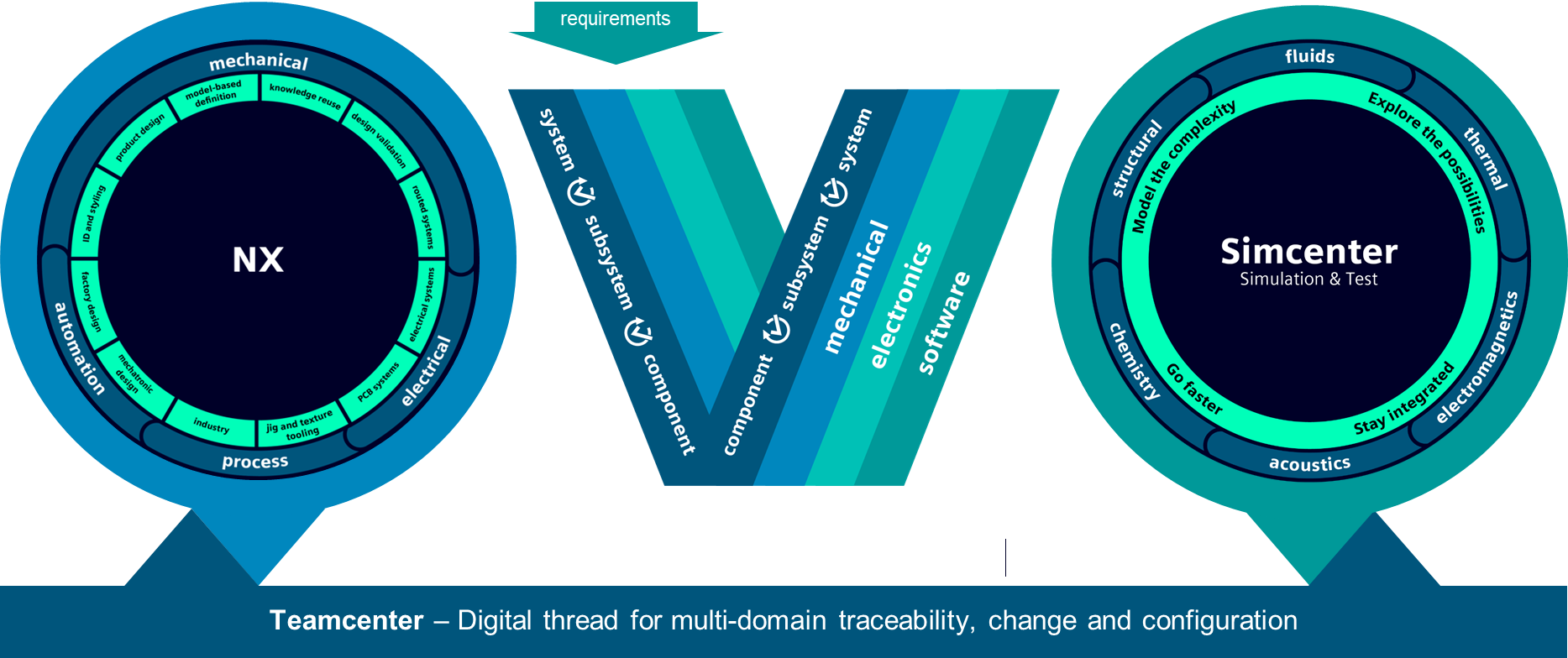

The Simcenter portfolio encompasses a range of solutions centered around the Digital Twin concept, which provides a virtual representation of physical systems. This allows for comprehensive simulation and testing across the entire product lifecycle, ensuring that products are optimized for performance and reliability.

Key Components of the Simcenter Portfolio

- Digital Twin Technology: The foundation of the Simcenter suite is its ability to create a comprehensive Digital Twin. This involves integrating data from various stages of product development to simulate real-world conditions, facilitating better decision-making and innovation.

- Simulation Solutions:

- Mechanical Simulation: Tools like Simcenter 3D, Nastran, and Femap enable engineers to conduct structural analysis, durability assessments, and more, ensuring that mechanical products meet necessary performance standards.

- CFD and Thermal Analysis: Simcenter STAR-CCM+ and FLOEFD provide advanced computational fluid dynamics (CFD) capabilities for analyzing fluid flow, heat transfer, and chemical reactions in products.

Electromagnetics: Solutions such as Simcenter MAGNET and E-Machine Design focus on electromagnetic compatibility and performance, critical for designing modern electronic devices.

- Physical Testing: The Simcenter Testlab and SCADAS systems facilitate real-world testing, allowing teams to validate simulations and ensure product reliability through physical data acquisition and analysis.

- Autonomy and MDAO: Simcenter Prescan provides a platform for validating automated and connected driving systems, while HEEDS supports multidisciplinary design analysis and optimization, driving innovation through automated workflows.

- Cloud Solutions: With high-performance computing (HPC) capabilities and cloud-based data sharing, the Simcenter portfolio enhances collaboration and efficiency, enabling teams to work on simulations from anywhere.

- System Simulation: Tools like Simcenter Amesim and Flomaster allow for the modeling of complex systems, enabling engineers to assess interactions between mechanical, thermal, and fluid systems early in the development process.

Addressing Engineering Challenges

The Simcenter portfolio is designed to tackle several key challenges faced by engineering teams today:

- Complexity Management: As products become more intricate, the need for integrated workflows that encompass multiple disciplines is crucial. The Simcenter tools are tailored to streamline these workflows, making it easier to manage complex engineering tasks.

- Sustainability: With growing urgency around sustainability, Simcenter enables engineers to balance performance with environmental considerations, optimizing designs for energy efficiency and reduced waste.

- Time-to-Market Pressure: The ability to simulate and test products digitally reduces development timelines, allowing companies to respond swiftly to market demands and customer customization needs.

Conclusion

The Simcenter portfolio is not just a collection of tools—it is an integrated ecosystem that transforms how engineering teams approach product development. By leveraging the capabilities of simulation, testing, and data management, organizations can enhance productivity, drive innovation, and ultimately deliver better products. As industries continue to evolve, embracing the comprehensive solutions offered by Simcenter will be essential for maintaining a competitive edge in the market.